Ke hoʻohālikelike ʻia me nā motika asynchronous, loaʻa nā pono o ka mana kiʻekiʻe, ka hana kiʻekiʻe, nā ʻāpana rotor hiki ke ana, ka ea nui ma waena o ka stator a me ka rotor, ka hana hoʻomalu maikaʻi, ka liʻiliʻi liʻiliʻi, ke kaumaha māmā, ka hana maʻalahi, kiʻekiʻe torque / inertia ratio, etc. mana (wikiwiki kiʻekiʻe, kiʻekiʻe torque), hana kiʻekiʻe a me ka miniaturization.

Hoʻokumu ʻia nā kaʻa kaʻa hoʻokahi me nā stators a me nā rotors. ʻO ka stator ka like me nā motika asynchronous, nona nā wili ʻekolu-phase a me nā cores stator. Hoʻokomo ʻia nā mea magnetized pre-magnetized (magnetized) mau ma luna o ka rotor, a hiki ke hoʻokumu ʻia kahi māla magnetic ma nā wahi a puni me ka ʻole o ka ikehu o waho, e hoʻomaʻamaʻa i ka ʻōnaehana kaʻa a mālama i ka ikehu. Hōʻike kēia ʻatikala i nā pōmaikaʻi piha o ka hoʻolaha ʻana i nā motor synchronous magnet permanente e pili ana i nā ʻano o nā motors synchronous magnet mau loa.

1. ʻO nā mea maikaʻi loa o ka mīkini paʻa magnet synchronous

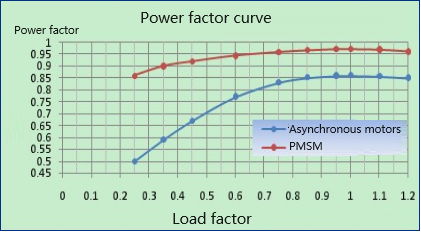

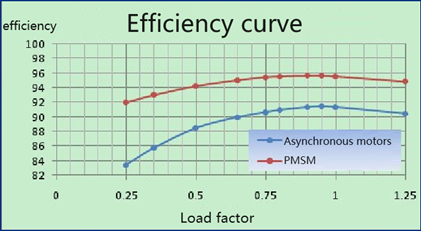

(1) No ka mea, ua hana ʻia ka rotor me nā magnet mau loa, ua kiʻekiʻe ke kiʻekiʻe o ka flux magnetic, ʻaʻohe koi ʻia o kēia manawa, a ua hoʻopau ʻia ka nalowale o ka excitation. Ke hoʻohālikelike ʻia me nā kaʻa asynchronous, ua hoʻemi ʻia ke ʻano o ka excitation o ka stator winding a me ke keleawe a me ka hao o ka rotor, a ua hoʻemi nui ʻia ka manawa reactive. Ma muli o ka hoʻonohonoho ʻana o ka stator a me ka rotor magnetic potentials, ʻaʻohe o ka hao hawewe kumu o ka rotor core, no laila ʻoi aku ka kiʻekiʻe o ka pono (pili i ka mana hana) a me ke kumu mana (pili i ka mana reactive) ma mua o nā kaʻa asynchronous. Hoʻolālā pinepine ʻia nā motor synchronous magnet i loaʻa i ke kumu mana kiʻekiʻe a me ka maikaʻi ʻoiai ke holo nei ma lalo o ka haʻahaʻa māmā.

I ka emi ʻana o ka 50% o ka ukana o nā kaʻa asynchronous maʻamau, hāʻule nui kā lākou hana hana a me ka mana mana. Ke hoʻololi nui ʻia ka nui o ka ukana o Mingteng permanent magnet synchronous motors he 25% -120%, ʻaʻole loli nui kā lākou hana hana a me ka mana mana, a ʻo ka hoʻokō pono ʻana he> 90%, a ʻo ke kumu mana he> 0.85. He mea koʻikoʻi ka hopena hoʻopakele ikehu ma lalo o ka haʻawe māmā, ka ukana loli a me ka ukana piha.

(2) Loaʻa i nā ʻenekini synchronous mau manaʻo paʻa nā waiwai mechanical a ʻoi aku ke kūpaʻa ʻana i nā haunaele torque kaʻa ma muli o nā loli ukana. Hiki ke hana ʻia ke kumu rotor o kahi kaʻa kaʻa synchronous magnet paʻa i kahi ʻano hollow e hōʻemi ai i ka inertia rotor, a ʻoi aku ka wikiwiki o ka manawa hoʻomaka a me ka braking ma mua o ka mīkini asynchronous. ʻO ke kiʻekiʻe torque / inertia ratio e hoʻolilo i nā motika synchronous magnet mau i kūpono no ka hana ma lalo o nā kūlana pane wikiwiki ma mua o nā kaʻa asynchronous.

(3) ʻOi aku ka liʻiliʻi o ka nui o nā kaʻa kaʻa synchronous mau loa ma mua o nā kaʻa asynchronous, a ʻoi aku ka māmā o ko lākou kaumaha. Me nā kūlana hoʻoheheʻe wela like a me nā mea insulation, ʻoi aku ka nui o ka mana o nā kaʻa kaʻa hoʻopaʻapaʻa paʻa mau ma mua o ʻelua mau manawa o nā kaʻa asynchronous ʻekolu.

(4) Ua maʻalahi loa ka hoʻolālā rotor, maʻalahi ka mālama a hoʻomaikaʻi i ka paʻa o ka hana.

No ka mea pono e hoʻolālā ʻia nā kaʻa asynchronous ʻekolu-phase me kahi kumu mana kiʻekiʻe, pono e hana liʻiliʻi loa ka lewa ma waena o ka stator a me ka rotor. I ka manawa like, he mea koʻikoʻi ka like ʻole o ka ea i ka hana palekana a me ka leo haʻalulu o ka kaʻa. No laila, koʻikoʻi nā koi o ke ʻano a me ke kūlana a me ka concentricity hui o ka motor asynchronous, a he liʻiliʻi ke kūʻokoʻa o ke koho ʻae ʻana. Hoʻohana maʻamau nā ʻenekini asynchronous me nā kumu nui aʻe i nā bearings lubrication ʻauʻau aila, pono e hoʻopiha ʻia me ka ʻaila lubricating i loko o ka manawa hana. ʻO ka leaka ʻaila a i ʻole ka hoʻopiha piha ʻole ʻana o ka lua aila e hoʻolalelale i ka hāʻule ʻole o ka bearing. I ka mālama ʻana i nā motika asynchronous ʻekolu-phase, ʻo ka mālama ʻana i nā bearings e pili ana i kahi hapa nui. Eia kekahi, ma muli o ka loaʻa ʻana o ka manawa i hoʻokomo ʻia i loko o ka rotor o ka motika asynchronous ʻekolu, ʻo ka pilikia o ka hoʻoheheʻe uila o ka bearing ua hopohopo pū ʻia e nā mea noiʻi he nui i nā makahiki i hala.

ʻAʻohe pilikia like ʻole nā motor synchronous magnet. Ma muli o ka nui o ka ea ea o ka magnet synchronous motor, ʻaʻole ʻike ʻia nā pilikia ma luna e ka liʻiliʻi liʻiliʻi o ka ea asynchronous i ka mīkini synchronous. I ka manawa like, hoʻohana nā bearings o ka motor synchronous magnet mau i nā bearings grease-lubricated me nā uhi lepo. Ua hoʻopaʻa ʻia nā bearings me ka nui kūpono o ka momona kiʻekiʻe i ka wā e haʻalele ai i ka hale hana. ʻOi aku ka kiʻekiʻe o ke ola lawelawe o nā bearings motor synchronous mau loa ma mua o ka mīkini asynchronous.

I mea e pale aku ai i ke au o ke au mai ka corroding i ka bearing, Anhui Mingteng permanent magnet motor apono i ka insulation manao no ka bearing hui ma ka huelo hope, hiki ke hoʻokō i ka hopena o ka insulating i ka bearing, a me ke kumu kūʻai ua emi loa ma mua o ka insulating ka bearing. No ka hōʻoia ʻana i ke ola lawelawe maʻamau o ka lawe ʻana i ka kaʻa, ʻo ka ʻāpana rotor o nā kaʻa hoʻokele pololei a pau o Anhui Mingteng he ʻano kākoʻo kūikawā, a ʻo ka hoʻololi ʻana o nā bearings ma ka pūnaewele e like me nā kaʻa asynchronous. Hiki i ka hoʻololi ʻana a me ka mālama ʻana ke mālama i nā kumukūʻai logistic, mālama i ka manawa mālama, a ʻoi aku ka maikaʻi o ka hōʻoia ʻana i ka hilinaʻi o ka mea hoʻohana.

2. Nā hoʻohana maʻamau o nā ʻenekini hoʻopaʻa magnet mau e pani ana i nā motika asynchronous

2.1 Hoʻoponopono alapine ʻokoʻa kiʻekiʻe-voltage ultra-high-efficiency ʻekolu-phase mau loa magnet synchronous motor no ka wili kū i ka ʻoihana sima.

E lawe i ka mīkini paʻa mau loa kiʻekiʻe-kiʻekiʻe ka hoʻololi ʻana i ka mīkini hoʻololi like ʻole TYPKK1000-6 5300kW 10kV. ʻO kēia huahana ka mua o ka home high-voltage permanent magnet motor ma luna o 5MW no ka hoʻololi ʻana i ka wili kūpaʻa i hāʻawi ʻia e Anhui Mingteng no kahi ʻoihana hale hale ma 2021. Ke hoʻohālikelike ʻia me ka ʻōnaehana kaʻa asynchronous mua, hiki i ka 8% ka hoʻopakele mana, a hiki i ka piʻi ʻana o ka hana ke hiki i 10%. ʻO 80% ka awelika o ka ukana, ʻo 97.9% ka pono o ka mīkini paʻa paʻa, a ʻo ke kumukūʻai mālama mana makahiki: (18.7097 miliona yuan ÷ 0.92) × 8% = 1.6269 miliona yuan; ʻo ke kumukūʻai mālama mana i nā makahiki he 15: (18.7097 miliona yuan ÷ 0.92) × 8% × 15 makahiki = 24.4040 miliona yuan; loaʻa ka hoʻopukapuka pani i loko o 15 mahina, a loaʻa ka hoʻihoʻi ʻana i ka hoʻopukapuka no 14 mau makahiki.

Ua hāʻawi ʻo Anhui Mingteng i kahi pūʻulu piha o nā mea hoʻololi wili kuʻekuʻe no kahi hui kūkulu hale ma Shandong (TYPKK1000-6 5300kW 10kV)

2.2 Haʻahaʻa haʻahaʻa-hoʻomaka ponoʻī ultra-kiʻekiʻe-efficiency ʻekolu-phase mau loa magnet synchronous kaʻa no nā mea hui ʻoihana kemika.

E lawe i ka mīkini paʻa mau loa-kiʻekiʻe-kiʻekiʻe ka hoʻololi ʻana i ka mīkini hoʻololi like ʻole TYCX315L1-4 160kW 380V. Ua hāʻawi ʻia kēia huahana e Anhui Mingteng i ka makahiki 2015 no ka hoʻololi ʻana o nā mīkini mixer a me nā mīkini crusher i ka ʻoihana kemika. Kūpono ʻo TYCX315L1-4 160kW 380V no nā kūlana hana mixer. Ma ka helu ʻana i ka hoʻohana ʻana i ka ikehu no kēlā me kēia ʻāpana manawa, ua helu ka mea hoʻohana i ka 160kw permanent magnet synchronous motor e mālama i ka 11.5% ʻoi aku ka uila ma mua o ka mīkini asynchronous mua me ka mana like. Ma hope o ʻeiwa mau makahiki o ka hoʻohana maoli ʻana, ʻoluʻolu loa nā mea hoʻohana i ka nui o ka mālama ʻana i ka mana, ka piʻi ʻana o ka mahana, ka walaʻau, ka wā a me nā hōʻailona ʻē aʻe o Mingteng permanent magnet synchronous motor i ka hana maoli.

Hāʻawi ʻo Anhui Mingteng i ke kākoʻo hoʻololi mixer no kahi hui kemika ma Guizhou (TYCX315L1-4 160kW 380V)

3. Nā pilikia e mālama ai nā mea hoʻohana

3.1 Ke ola kaʻa ʻO ke ola o ke kaʻa holoʻokoʻa e pili ana i ke ola o ka bearing. Hoʻohana ka hale kaʻa i ka pae palekana IP54, hiki ke hoʻonui ʻia i IP65 ma lalo o nā kūlana kūikawā, e hoʻokō ana i nā koi hoʻohana o ka hapa nui o ka lepo a me ka lepo. Ma lalo o ke kūlana o ka hōʻoia ʻana i ka coaxiality maikaʻi o ka hoʻokomo ʻana i ka hoʻonui ʻia ʻana o ka pahu kaʻa a me ka ukana radial kūpono o ke kumu, ʻoi aku ka liʻiliʻi o ke ola lawelawe o ka lawe kaʻa ma mua o 20,000 mau hola. ʻO ka lua, ʻo ia ke ola o ka mea hoʻoluʻu hoʻoluʻu, ʻoi aku ka lōʻihi ma mua o ke ʻano o ka mīkini hana capacitor. Ke holo lōʻihi i loko o kahi lepo lepo a haʻahaʻa, pono e wehe mau i nā mea paʻa i hoʻopili ʻia i ka peʻahi e pale ai i ka puhi ʻana ma muli o ka overload.

3.2 Ka hāʻule ʻole a me ka pale ʻana i nā mea magnet mau loa

ʻO ke koʻikoʻi o nā mea magnet paʻa mau i nā kaʻa kaʻa mau loa e ʻike pono ʻia, a ʻo kā lākou kumukūʻai e ʻoi aku ma mua o 1/4 o ke kumu kūʻai o ke kaʻa holoʻokoʻa. ʻO Anhui Mingteng mau mea hoʻohana i nā mea hoʻohana kiʻekiʻe o ka ikehu ikehu a me ke kiʻekiʻe intrinsic coercivity sintered NdFeB, a me nā māka maʻamau e komo pū me N38SH, N38UH, N40UH, N42UH, etc. kokoke ke kila, e hōʻoiaʻiʻo ana i ka symmetry o ke kaapuni magnetic a me ka maikaʻi o ka hui kila magnetic.

Hiki ke holo no ka manawa lōʻihi ma lalo o ka piʻi ʻana o ka wela i ʻae ʻia o ka wili kaʻa, a ʻaʻole ʻoi aku ka kiʻekiʻe o ka demagnetization kūlohelohe o ke kila magnetic ma mua o 1‰. Pono nā mea magnet mau loa i ka uhi ʻia o ka ʻili e kū i ka hoʻāʻo ʻana o ka paʻakai ma mua o 24 mau hola. No nā kaiapuni me ka oxidative corrosion koʻikoʻi, pono nā mea hoʻohana e hoʻokaʻaʻike i ka mea hana e koho i nā mea magnet paʻa me ka ʻenehana pale kiʻekiʻe.

4. Pehea e koho ai i ka moto magnet mau e pani ai i ka moto asynchronous

4.1 E hoʻoholo i ke ʻano ukana

ʻO nā ukana like ʻole e like me nā wili pōleʻa, nā pā wai, a me nā mea pā he ʻokoʻa nā koi hana no nā kaʻa, no laila he mea nui ke ʻano ukana no ka hoʻolālā ʻana a i ʻole ke koho ʻana.

4.2 E hoʻoholo i ke kūlana ukana o ka motika i ka hana maʻamau

Ke holo mau nei ke kaʻa me ka ukana piha a i ʻole ka haʻahaʻa māmā? A i ʻole he haʻahaʻa kaumaha i kekahi manawa a i kekahi manawa haʻahaʻa māmā, a pehea ka lōʻihi o ka hoʻololi ʻana o ka pōʻai māmā a me ke kaumaha?

4.3 E hoʻoholo i ka hopena o nā mokuʻāina ukana ʻē aʻe ma ka kaʻa

Nui nā hihia kūikawā o ke kūlana haʻahaʻa o ka mīkini ma ka pūnaewele. No ka laʻana, pono ka ukana conveyor kāʻei e halihali i ka ikaika radial, a pono paha e hoʻololi ʻia ka motika mai nā ʻeke kinipōpō a i nā bearings roller; inā he nui ka lepo a i ʻole ka aila, pono mākou e hoʻomaikaʻi i ka pae pale o ka kaʻa.

4.4 Ka wela ambient

ʻO ka mahana ambient ma ka pūnaewele ka mea e pono ai mākou e nānā i ka wā o ke kaʻina koho kaʻa. Hoʻolālā ʻia kā mākou mau kaʻa maʻamau no kahi mahana ambient o 0 ~ 40 ℃ a i lalo paha, akā ʻike pinepine mākou i nā kūlana i ʻoi aku ka kiʻekiʻe o ka mahana ambient ma mua o 40 ℃. I kēia manawa, pono mākou e koho i kahi kaʻa me ka mana kiʻekiʻe a i ʻole kahi kaʻa i hoʻolālā ʻia.

4.5 ʻO ke ʻano o ka hoʻonohonoho ʻana ma ka pūnaewele, nā ana hoʻonohonoho kaʻa

ʻO ke ʻano o ka hoʻonohonoho ʻana ma ka pūnaewele, nā ana hoʻonohonoho kaʻa, nā ʻano hoʻonohonoho ma ka pūnaewele a me nā ana hoʻonohonoho ʻana he ʻikepili pono e kiʻi ʻia, a i ʻole ke kiʻi kiʻi ʻoniʻoni mua, a i ʻole nā ana o ka hoʻonohonoho ʻana, nā ana kumu a me kahi wahi hoʻonoho kaʻa. Inā loaʻa nā palena ākea ma ka pūnaewele, pono paha e hoʻololi i ke ʻano hoʻoluʻu kaʻa, kahi o ka pahu alakaʻi kaʻa, etc.

4.6 Nā kumu kaiapuni ʻē aʻe

Nui nā mea kaiapuni ʻē aʻe i ka hopena i ke koho kaʻa, e like me ka lepo a i ʻole ka ʻaila pollution e pili ana i ka pae palekana kaʻa; no ka laʻana, i nā kaiapuni moana a i ʻole nā kaiapuni me ka pH kiʻekiʻe, pono e hoʻolālā ʻia ke kaʻa no ka pale corrosion; i nā kaiapuni me ka vibration kiʻekiʻe a me ke kiʻekiʻe kiʻekiʻe, aia nā manaʻo hoʻolālā like ʻole.

4.7 Ke noiʻi ʻana i nā ʻāpana kaʻa asynchronous kumu a me nā kūlana hana

(1) Ka ʻikepili papa inoa: helu ʻia ka voltage, helu ʻia ka wikiwiki, helu ʻia i kēia manawa, helu mana helu, pono, hoʻohālike a me nā ʻāpana ʻē aʻe

(2) Ke ala hoʻonohonoho: e kiʻi i ke kiʻi kiʻi ʻoniʻoni mua, nā kiʻi hoʻonohonoho ma ka pūnaewele, etc.

(3) Nā palena hana maoli o ka kaʻa mua: ka mana, ka mana, ka wela, a me nā mea ʻē aʻe.

Ka hopena

He kūpono loa nā kaʻa hoʻokalakupua magnet paʻa no ka hoʻomaka kaumaha a me nā noi māmā. ʻO ka hoʻolaha ʻana a me ka hoʻohana ʻana i nā kaʻa kaʻa synchronous magnet mau loaʻa nā pōmaikaʻi hoʻokele waiwai a me ka pilikanaka a he koʻikoʻi nui ia i ka mālama ʻana i ka ikehu a me ka hoʻemi ʻana. Ma ke ʻano o ka hilinaʻi a me ka paʻa, loaʻa nā pono waiwai nui nā motor synchronous magnet mau loa. ʻO ke koho ʻana i nā mīkini paʻa paʻa paʻa kiʻekiʻe he hoʻolimalima hoʻokahi manawa me nā pōmaikaʻi lōʻihi.

ʻO Anhui Mingteng Permanent Magnet Electromechanical Equipment Co., Ltd. (https://www.mingtengmotor.com/) ke kālele nei i ka noiʻi, hoʻomohala, hana a me ke kūʻai ʻana i nā kaʻa kaʻa hoʻopaʻapaʻa kūpaʻa ultra-high-efficiency no 17 makahiki. ʻO kāna mau huahana e uhi i ka piha piha o ka volta kiʻekiʻe, ka haʻahaʻa haʻahaʻa, ke alapine mau, ke alapine hoʻololi, ka maʻamau, ka pahū-hōʻoia, ka hoʻokele pololei, nā wili uila, a me nā mīkini āpau, me ka manaʻo e hāʻawi i ka ikaika hoʻokele maikaʻi no nā lako ʻoihana.

Loaʻa i nā kaʻa kaʻa magnet mau loa o Anhui Mingteng ka nui o ka hoʻokomo ʻana i waho e like me nā motika asynchronous i hoʻohana nui ʻia i kēia manawa, a hiki ke hoʻololi piha i nā motika asynchronous. Eia kekahi, aia kahi hui loea loea e hoʻolālā a hāʻawi i nā mea kūʻai aku i nā hoʻololi hoʻololi manuahi. Inā pono ʻoe e hoʻololi i nā kaʻa asynchronous, e ʻoluʻolu e hoʻokaʻaʻike mai iā mākou, a e lawelawe mākou iā ʻoe me ka naʻau holoʻokoʻa!

Ka manawa hoʻouna: ʻAukake-23-2024